|

| About Volunteer Donate |

| Art parts wheels |

| Featured bikes for sale |

| Folders Recumbents Tandems Trikes |

| Fun Bikes |

| Museum Bikes |

| Racks Stands Trainers Rollers |

|

Museum Bikes

Bicycles of historical interest on display at New Bo Bikes.

| 1970s Browning Mark ? 10 speed. |

|---|

|

During the bicycle boom of the late 1960s to early 1970s, many non-bicycle companies believed there was money to be made by selling bicycles. Rather than spend a lot on production facilities, most companies bought bicycles from the regular mass market bicycle manufacturers to be sold with their names on them. This practice was nothing new. Colonel Albert Pope started that in the 1870s. The BMA/6 (Bicycle Manufacturers of America) : AMF, Columbia, Huffy, Murray, Ross and Schwinn all made bikes for other retailers. Many foreign companies did the same for USA companies.

This particular bicycle was made in Belgium for the Browning Arms Company who were expanding into a variety of outdoor equipment products. They were sold at Browning gun dealers. |

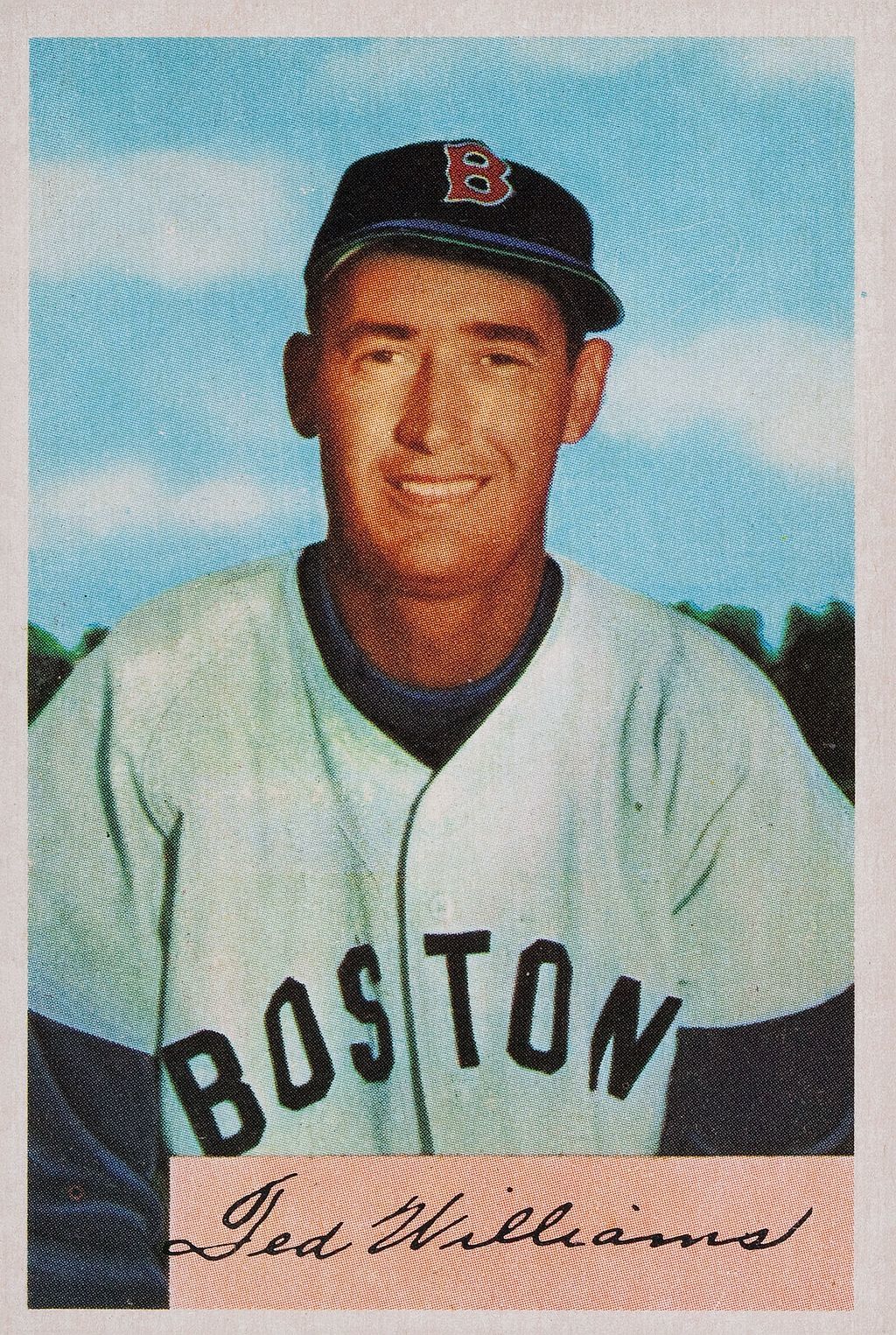

| 1973 Sears Free Spirit Ted Williams Signature Model 10 Speed |

|---|

Ted Williams was arguably the best baseball player of all time. Like many professional athletes, he signed an endorsement deal for his signature to be put on all sorts of outdoors and sporting goods sold at Sears department stores. Ted served as a military fighter pilot during World War II and the Korean War. 39 combat missions in Korea, half of those as John Glenn's wingman. No doubt he would have set the all time home run record if he had played all those years he served in the military. Ted Williams became infamous after his death. His children fought over cremation vs cryogenic freezing so he could be revived in the future. After he died, Ted Williams was quickly cryogenically frozen so he could be revived in the future when the technology was ready. His son is also frozen at the same company in Arizona. This particular bike would not pass Consumer Product Safety Commission standards enacted just a few years later. Wing Nuts were banned along with other protrusions that might injure a rider. Made in Austria by Steyr. One of Sears primary suppliers of bicycles. |

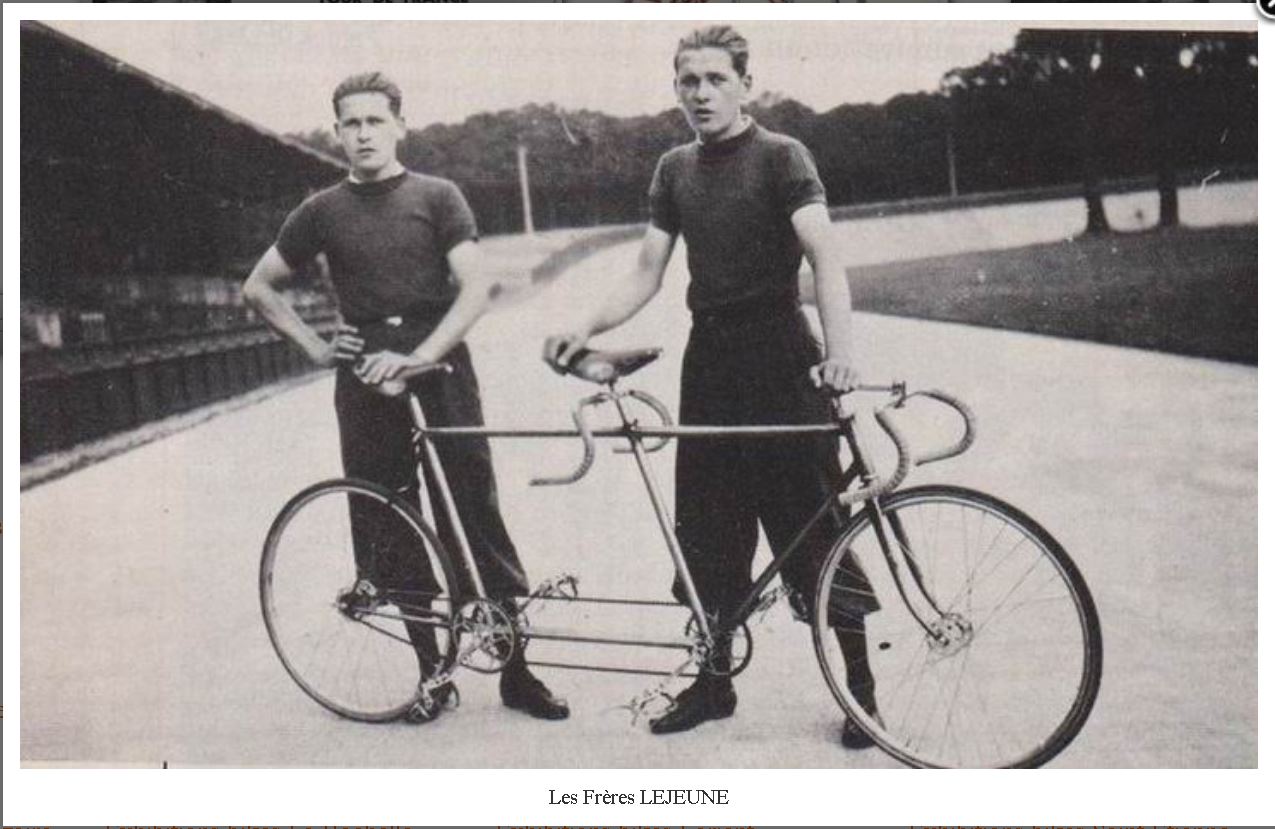

| 1972 LeJeune |

|---|

In 1947, the twin brothers Roger and Marcel Lejeune, former amateur racing cyclists, set out to manufacture bicycles on the south-eastern outskirts of Paris. Lejeune sponsored or co-sponsored professional cycling teams from 1961 through to 1980: This particular LeJeune bicycle was an entry level mass market bike from the bike boom of the 1960s to mid 1970s. Very similar to many Hostler, Gitane, Jeunet, Motobecane and Peugeot bicycles.

|

| 1973 Mossberg Super Deluxe 10 speed |

|---|

During the bicycle boom of the late 1960s to early 1970s, many non-bicycle companies believed there was money to be made by selling bicycles. Rather than spend a lot on production facilities, most companies bought bicycles from the regular mass market bicycle manufacturers to be sold with their names on them. This practice was nothing new. Colonel Albert Pope started that in the 1870s. The BMA/6 (Bicycle Manufacturers of America) : AMF, Columbia, Huffy, Murray, Ross and Schwinn all made bikes for other retailers. Many foreign companies did the same for USA companies. This Mossberg bicycle was sold by the O.F. Mossberg & Sons firearms company who are most famous for their shotguns. The bicycle was manufactured by one of the BMA/6 manufacturers in the early 1970s. One unique item is the original owner’s initials embossed on a small plate on the frame. |

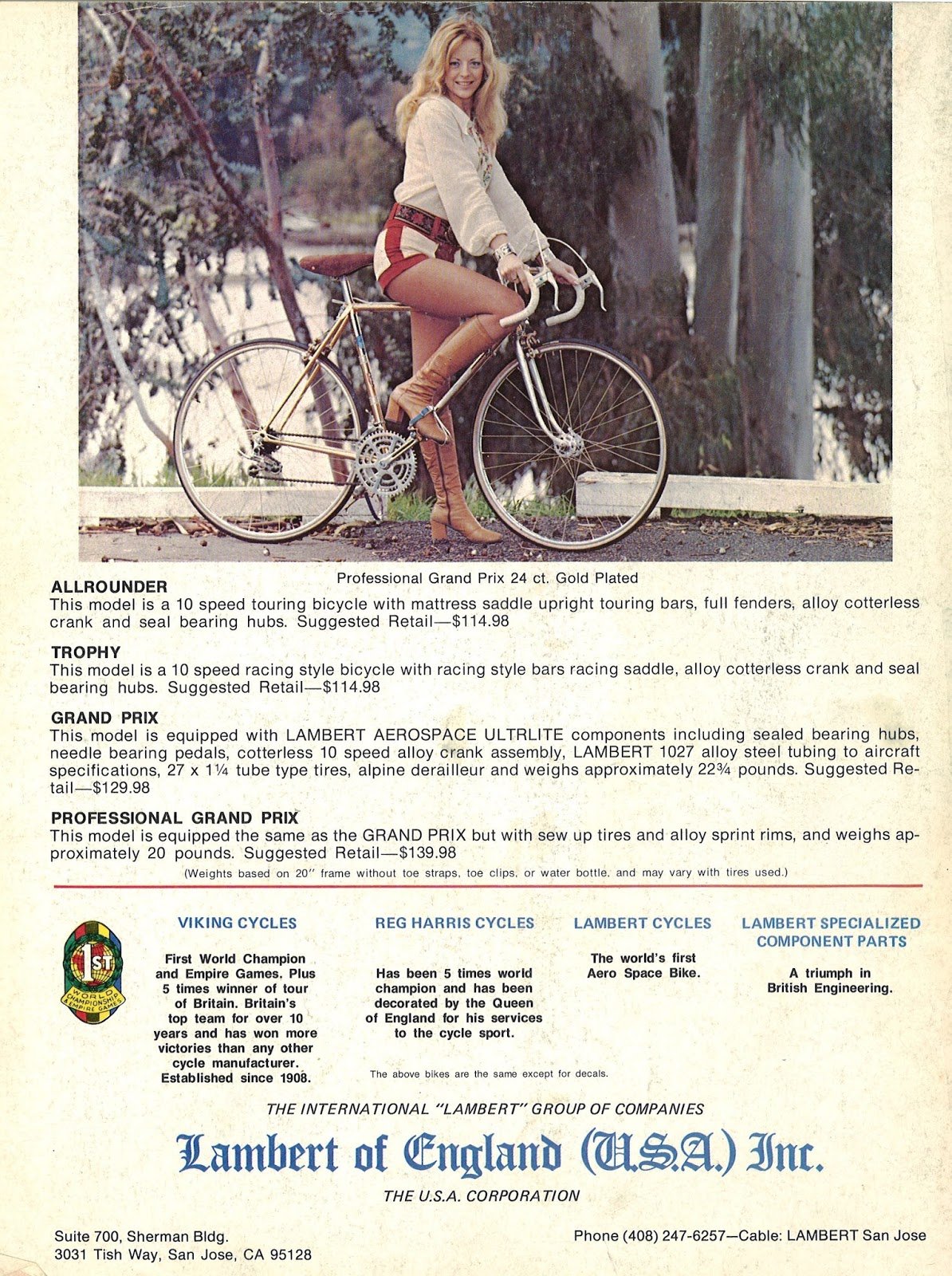

| Viscount Aerospace Grand Prix |

|---|

Lambert of England had the hottest bike adverts in the early 1970s for their Aerospace bikes featuring private jets and hot pants. The Lambert Aerospace bicycles were a disaster from the start. The company made most of the components themselves, copying the look and design of other brands but did none of the materials engineering to make those parts reliable. The worst ever rear derailleur was quickly replaced by the company. Undersized needle bearings in the pedals would get chewed up if you pedaled hard. The pedal axles were not heat treated high strength steel so those got bent. The bottom bracket had 2 sealed cartridge bearings pressed directly into the frame (no threads). A bad practice repeated later on in many carbon fibre frames. The bottom bracket axle had 2 grooves cut in it for circlips to keep the axle from sliding sideways. The grooves greatly weakened the highly stressed axle. The 4 sided axle was not tapered so the crank would wobble. The amount of crank vs axle overlap was about 1/4". Normal 4 sided tapered cranks overlap the axle by just over 1/2". The crank bolts were chrome plated which made them brittle. To keep the cranks from wobbling, shop mechanics and owners would over tighten the bolts until they broke or the ends of the axle broke off. Riding with loose cranks would chew up the aluminum square hole. Replacing the entire crank set meant buying a very expensive special bottom bracket that threaded in to itself instead of the frame which was too thin to cut threads into. Add a new crank set and labor and that added up to as much as the bike cost new. The frames were weak. My first job was assembling Lamberts at a bike shop. The first box I opened up was a unhappy surprise. The head tube had snapped off the frame during shipping from England. There was no warranty and the shop owner was pissed. He never ordered any more to sell. I bought my first Lambert from the shop owner's son and it cracked down the side of the seat tube. I sold the bike to another shop rat who drilled holes through the frame and seat post and bolted the seat post into place. Fortunately he got run over a few weeks later (unhurt) and the bike destroyed before he could get really injured. About the only good Lambert part was the sealed bearing hubs. Kinda chunky looking but they were one of the first sealed bearing hubs for bicycles. Yamaha bought Lambert and changed the name to Viscount. Republican President Richard Nixon signed the Consumer Product Safety Act in to law in 1972 to create the Consumer Product Safety Commission. Their very first recall for a bicycle product was Viscount bicycles to replace the "Death Fork". A solid aluminum fork with a pressed on steel steering tube. The fork had a habbit of falling apart. The company's initial repair attempt was to drill a hole through the steerer and the aluminum plug. That created a stress riser and then the forks would just snap off. Fall apart or break off, the rider would loose some teeth and wake up in a hospital 3 days later wondering why their jaws were wired shut and having no memory of any accident. A nationwide recall campaign with a toll free 800 phone number was launched. Owners would call the 800 number to provide their name and address. Owners would receive a box with a nice chrome plated steel fork threaded way down the steerer, (one size fits all), a new headset, a coupon for service and instructions to take it to a local bike shop. I replaced scores of these forks on bikes sold by other bike shops. The bike shop would replace the fork (cutting it to proper length to fit a particular size frame) and mail in a coupon that reimbursed the shop $50 for labor! That was a lot for a 10 minute job. We had to sign the coupon stating we destroyed the fork. Many were cut off at the crown and repurposed as wheel stands. The bike in our museum still has the original fork. Federal law prohibits reselling any recalled product that hasn't been repaired. Yamaha dropped the entire Aerospace line and sold normal lugged frame bikes from Asian makers that had no safety issues. |

These Museum bikes are of historical interest but are actually lousy bikes to ride. Many entry level bikes from the bike boom were heavy and poorly made. Fast forward 40 years and the many cheap Asian bikes are not any better. Many branded bikes were chosen for cost considerations only. One of the most famous is John Deere bicycles. Low grade bicycles from Taiwan when Taiwan bicycle companies were just starting out and hadn't learned to make quality bikes. JDs are mostly collectiable in the eyes of farmers who own the quality tractors and other farm equipment. The bicycles were a bit of embarrasment to the company. Many were dumped on their own employees (here is your Christmas bonus). The brake levers on the men's ten speed were criminally bad. Designed to quickly fall apart and leave the rider with no brakes! BTW, there were John Deere bikes from over 100 years ago that are true museum items.

Copyright Rick Paulos 2024